In laser modules, raised operating temperatures can cause wavelength and power drift, and reduced efficiency. In this post we look at the effects of heat on your laser module, develop an understanding of it and outline techniques to keep waste heat under control.

Wavelength and Output Power

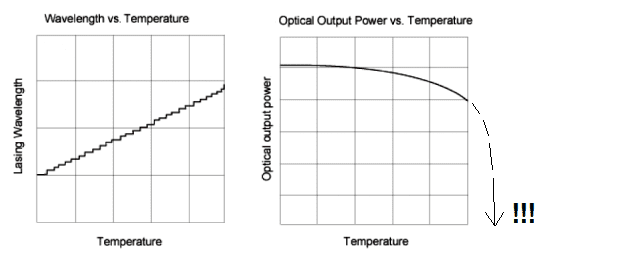

Both wavelength and output power (at constant current) are strong functions of the temperature of the laser diode. If the temperature increases too much, the laser power will be affected and can even drop to zero.

If you need a stable wavelength or predictable laser power, you must control the temperature of your laser diode.

Why does my laser module heat up?

Laser diodes use electrical current to stimulate the emission of light from the laser cavity.

The current is generated by applying a voltage to the terminals, so a certain amount of power (voltage x current) is required to operate the laser. Some of this power (typically 10-30%) is converted into light, but the rest is wasted.

Additionally, some of the optical power (typically 5-50%) is absorbed in the optical assembly. This power is also wasted.

For example, to get a 100mW laser beam you may need to supply anything up to 2000mW to the laser diode. All of the power which doesn’t make it into the laser beam is wasted as heat.

Where does the heat go?

The power wasted in the process of generating and forming the laser beam ends up heating the laser diode, the module, the optics and the surrounding environment.

The temperature of the laser diode, and its performance and predictability, are directly related to the distribution and management of this heat.

How can the heat be managed?

Regardless of the output power of a laser module, in order to prevent the heat building up in the laser diode and increasing its temperature, a thermal pathway must be created to allow the heat to flow away from the laser diode.

This pathway normally consists of a metal mounting for the laser diode, which is attached to the metalwork of the laser module case.

The surface area of the case must be sufficient to allow the heat to dissipate into the environment by conduction and/or convection, either directly or through thermally conductive mounting and heatsinking arrangements.

Where wavelength stability and thermal stabilization are critical, the PROdigii laser module from ProPhotonix incorporates thermal stabilisation of the laser diode in its compact, cylindrical package.

In the PROdigii laser module, heat generated by the laser diode is literally pumped out via an integrated Peltier thermo-electric cooling device (TEC). The pumped heat is then conducted through the metal components of the module body to the case, where it can be dissipated into the environment by a heatsink.

This is the key to PROdigii’s high power capability yet small size.

The Peltier device incorporated in the PROdigii digital laser has the added advantage that it works both ways: if the environment is too cold, the TEC pumps heat back into the laser diode to maintain it at the ideal operating temperature, thereby stabilizing both wavelength and optical performance.

Technical Support

At ProPhotonix, we have laser diode technology experts who can calculate, design, procure and advise on heatsinking and thermal management solutions to keep your lasers cool optimizing their performance for your application. Contact sales@prophotonix.com for support.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.

ProPhotonix laser module range includes laser modules by beam shape including crosshair lasers, line lasers and dot laser modules. Contact us for free expert advice on selecting the optimal solution for your system.