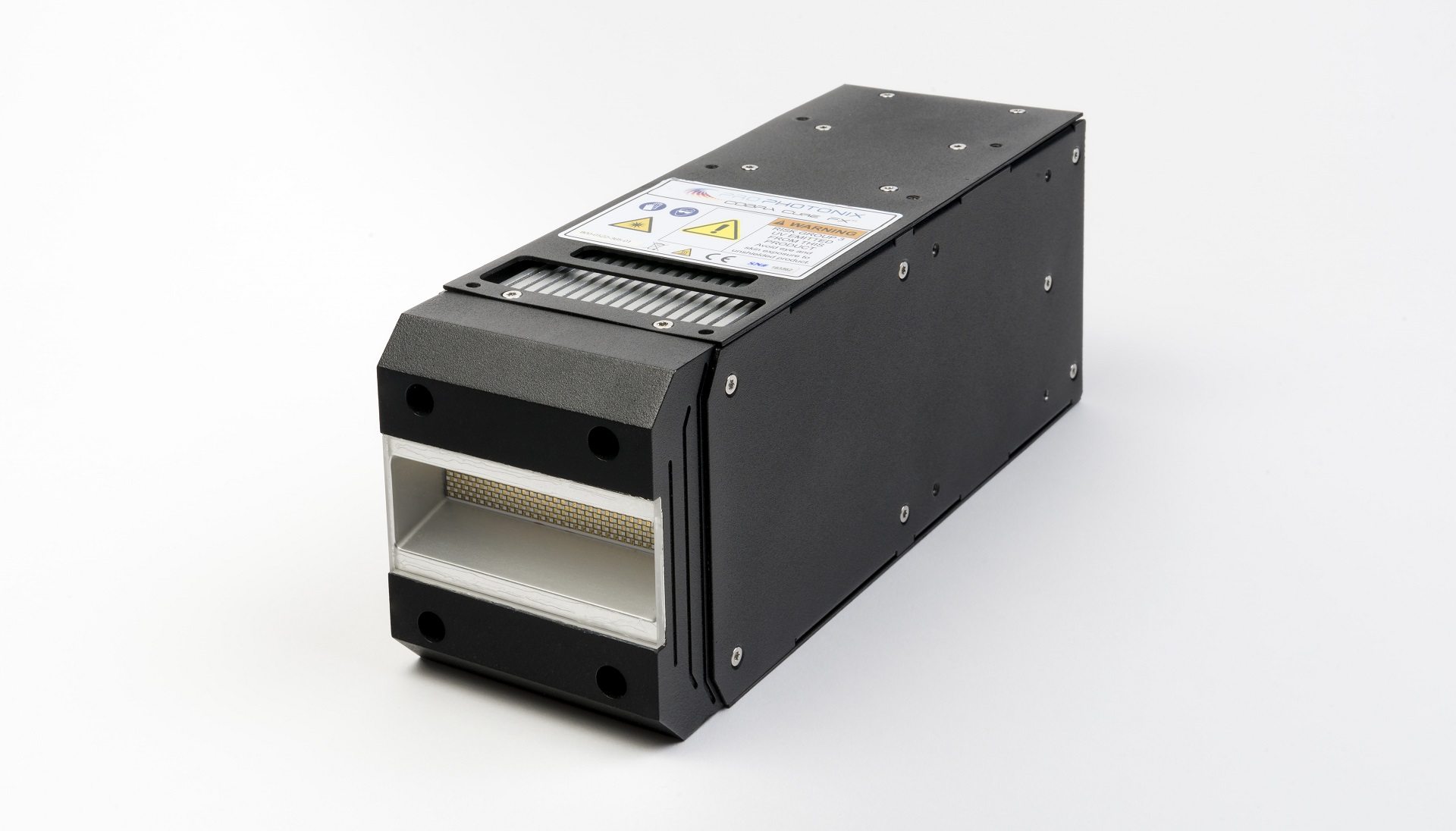

COBRA Cure FX3 UV LED Curing system delivers up to 20W/cm2 or 40J/cm2. Ideal for UV curing of inks, coatings and adhesives. A compact, scalable UV lamp with the benefits of LEDs and unique features for a consistent, reliable cure.

Compact, stackable, UV LED Curing System offering up to 20W/cm2 of highly uniform UV light.

Key Features:

- Intensity up to 20W/cm2, Energy density up to 40 J/cm2

- 365nm, 385nm. 395nm, 405nm and multi-wavelength options available

- Compact, stackable UV LED system

- Lifetime: 20,000 hours

- Instant on/off and intensity control

- Cold cure – ideal for heat sensitive materials

- No ozone. No mercury

Key Applications:

- UV Curing of inks, coatings and adhesives

- 3D Printing

COBRA Cure FX3 Features

A compact, scalable UV LED lamp, COBRA Cure FX3 incorporates the many benefits of a LED curing system as well as innovative features to ensure a consistent, reliable cure over the lifetime of the system. This high power UV lamp is available in a range of wavelengths from 365nm to 405nm as well as multi-wavelength options.

Intensity & Dose

Based on multiple 3rd party tests, the COBRA Cure FX3 offers industry-leading intensity and dose values for fan-cooled systems without compromising on lifetime and reliability. This is achieved through a combination of ProPhotonix’ in-house Chip-On-Board LED capabilities, in-house engineering team and over 25 years’ experience in designing and manufacturing LED-based systems.

Modular Design

The COBRA Cure FX3’s design offers edge to edge illumination making the system truly scalable with minimal drop in intensity at the edges. This UV LED Lamp is offered in modules of 75mm up to 600mm in a single housing to suit your specific application requirements.

Superior Intensity Control

The UV LED lamps can be factory set to a customer-specified linear intensity profile and maximum intensity value for performance consistency lamp to lamp. Due to the ability to monitor and drive each 10mm width LED segment, the COBRA Cure FX3 offers excellent intensity control and long lifetimes.

Need help to optimize for your application?

For comprehensive technical support. Talk to us.

Contact UsContact Us

Bernhard Russell

Inside Sales

Andrea Gregorio

Inside Sales

Market Leading Product Performance

UV LED Curing Systems are designed and built to deliver maximum performance throughout the lifetime of the products.

Flexibility to Adapt to Your Needs

Flexibility to configure or customize your product to your application requirements and flexible ongoing support to meet your business needs.

A Complete Solution Provider

We take a long-term view of customer relationships supporting you from concept to completion as well as with day to day business needs.

Other Products in the Range:

COBRA Cure FX1

5.4W/cm² Compact, UV LED curing system offering a stable, reliable cure over a long lifetime, ideal for printing and 3D printing applications.

View Details

COBRA CURE FX2

8.4W/cm² UV LED curing system is a compact, fan-cooled system offering excellent intensity control across varying conditions to ensure an even cure.

View Details

New COBRA Cure Mini

6W/cm² Compact, Light form factor UV LED curing system offers a cost-effective solution for high-speed single and multi-pass printers.

View Details

COBRA Cure FX1 Max

6.4W/cm² UV LED curing system has 20% higher intensity than the COBRA Cure FX1, well suited for limited space applications requiring higher intensity and dose.

View Details