The primary purpose of a machine vision lighting system is to identify features of interest in a target material. Once this data has been collected, the system will use the information to sort or grade material or determine whether defects are present.

Obtaining a good image is critical to the performance of a machine vision system and a better image can result in faster processing times, faster line speed and higher-quality products. When optimizing your machine vision lighting for your application, you’ll need to consider: wavelength, uniformity, angle of illumination and intensity. This post will outline these considerations.

Wavelength

To maximize system performance, selecting the most appropriate wavelength will ensure that the features of interest are enhanced. The optimal wavelength for a specific application will be determined by the optical properties of the target material and the features of interest as well as the spectral response of the camera. Learn more about Wavelength in Machine Vision Lighting in this post.

Uniformity

Non-uniformity in machine vision lighting will result in poor image quality and an unclear signal to the system. With non-uniform lights, the system software may struggle to differentiate between features of interest and non-uniformities caused by the lighting.

Angle of Illumination

In a machine vision application, the target object’s shape, surface structure, and material type will all influence the way light is reflected. In each application, the correct angle of illumination must be selected to obtain a high-quality image. Front lighting and backlighting are the most common configurations.

Intensity

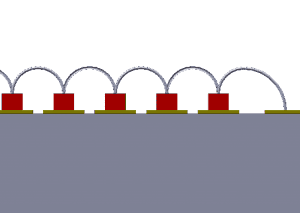

Having achieved good contrast in the image, higher intensities allow for a reduced camera capture time which in turn leads to higher run speeds. ProPhotonix utilizes a high density LED packaging method called Chip-on-Board LED technology. The high-density arrays built using this technology result in an extremely uniform, high-intensity light. This technology offers a number of other advantages in machine vision lighting applications. Learn more about Chip-on-board LED technology in Machine Vision Lighting here.

Machine Vision Lighting from ProPhotonix

ProPhotonix provides a wide range of compact, high intensity, LED Products for Machine Vision Lighting. Our high-performance products are designed to deliver reliable results in the field. Easily installed, these products are also fully-configurable to suit all your application needs, with a range of wavelengths, optical- and electronic options available. See the full range of LED products here.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.