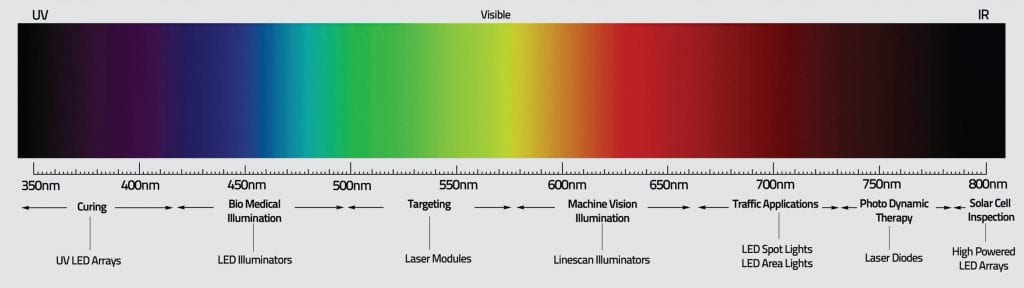

Machine vision inspection systems rely on the careful choice of illumination wavelength to enhance image contrast. Choosing the correct wavelength of light in machine vision lighting applications is important in order to enhance image features. In the following post, we look at the impact of wavelength in machine vision applications, and in particular, what wavelength is, and what the wavelength considerations for machine vision lighting are.

What is Wavelength in Machine Vision Lighting?

In machine vision lighting, wavelength is the color of the light that is used to illuminate an object and to enhance contrast. As camera systems have a different spectral response to that of the human eye, it is important to consider all sections of the spectrum and not just the visible light. Both ultra violet and infra-red light also play a major role in capturing specific features on or in the object being inspected.

Wavelength Considerations in Machine Vision Lighting

The ability to deliver light at a discrete wavelength offers the machine vision system designer more scope to enhance contrast. Machines built using white light and monochrome cameras do not necessarily offer the optimum contrast, i.e. red objects may appear the same as green and are therefore indistinguishable. In older systems, white light filters were typically used to improve the overall contrast of the system, but at the cost of reducing intensity. In the majority of applications, well chosen monochrome illumination generally offers more contrast.

1. Red, Green & Blue Illumination (RGB)

Many applications use smart cameras equipped with standard simple monochrome LED sources. The cameras that are used in linescan applications are most commonly monochrome.

Inspection systems use a broad color spectrum with a color camera to enhance image contrast. This is achieved by coating the top of blue LEDs with phosphor, which in turn re-emits the spectrum and produces a white light suitable for the majority of machine vision applications.

RGB is not used to generate a broad spectrum. It is, however, used in applications that use a monochromatic camera. When different colored objects for inspection are illuminated with red, green and blue (RGB) light, a monochrome camera can be used to view each color separately thus allowing a color image to be constructed with subsequent image processing. In this situation, it is important that the illuminator has the correct colors available at the sufficient intensity and that these colors can be addressed separately and synchronised with the vision system.

2. Infra-red Illumination (IR)

Wavelengths longer than the visible range are in the infra-red (IR) region. Infra-red illumination is used to diminish color effects in monochrome images by increasing the contrast of colored objects simplifying the inspection process and reducing the requirement for complex image pre-processing. Infra-red illumination, in conjunction with filters, can also be used as a way of reducing the effects of background noise from ambient illumination.

3. Ultra Violet Illumination (UV)

Wavelengths shorter than visible light are known as ultra violet (UV). UV light is invisible to the human eye and lies below the violet end of the visible spectrum. UV illuminators are used in fluorescence applications such as UV tracer and currency inspection applications, where the shorter UV wavelength is used to match the absorption characteristics of the tracer. Due to the inefficient nature of this process, intensity is an important consideration. Filtering the stimulation wavelength is also an important consideration of the wavelength spectrum, in order to ensure that it does not overlap with the fluoresced light.

Conclusion

Wavelength is a key consideration in machine vision applications for enhancing contrast and capturing information from the object under inspection. Selecting the correct wavelength in machine vision lighting to illuminate the object can be the difference between a high and a low quality vision system. By using high power illuminators, which are available from UV through visible to IR wavelengths, designers can optimize contrast without compromising image brightness or sensitivity.

Learn more in our whitepaper, Optimize your System Performance with Machine Vision Lighting.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.