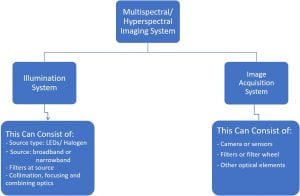

The field of spectral imaging, first pioneered by NASA to study the solar system, has witnessed remarkable advancements with the implementation of new illumination techniques. Hyperspectral imaging and multispectral imaging are at the heart of this revolution, empowering engineers and systems designers with the ability to obtain valuable spectral information in fields as diverse as food sorting, recycling, and chemical and pharmaceutical analysis.

Amidst this wealth of possibilities, finding the perfect imaging technique and the right light source for your specific application can be a daunting task. This blog series will help you harness the full potential of spectral imaging through the use of LED lighting.

What is Multispectral Imaging?

Multispectral imaging (MSI) is a powerful technique that analyzes images captured at specific wavelengths and has been around since the 1970s. In the early days, MSI used halogen lighting which required filters and cameras for proper illumination. These halogen lamps are becoming increasingly obsolete due to high heat, low efficiency, high maintenance and usage of environmentally hazardous materials. The evolution of LED lighting can remove the need for expensive and complicated camera and filter technology, simplifying the targeting of specific spectral signatures through the use of LEDs at the correct wavelength.

A classic example of multispectral imaging application is to assess fruits and vegetables such as apples, oranges, pears etc. MSI helps determine the quality of the fruit (or vegetable) in a non-invasive manner and can be used for disease detection, fruit ripeness/maturity estimation and more.

What is Hyperspectral Imaging?

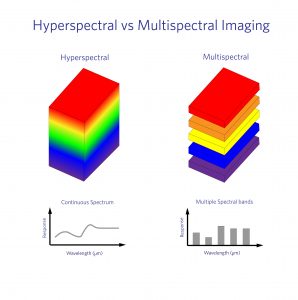

Hyperspectral imaging (HSI) is an advanced technique that takes spectral imaging to a new level of precision and detail. Unlike MSI, which captures images at specific discrete wavelengths, HSI acquires images across a vast number of continuous narrow bands (10-20 nm). To capture hyperspectral images, specialized hyperspectral cameras or sensors with hyperspectral illumination are employed. These instruments employ prisms, gratings, or interferometers to disperse incoming light across a sensor array into hundreds of detection bands. Each pixel in the resulting hyperspectral image contains a complete spectrum, providing detailed information about the reflectance or absorption characteristics of the imaged scene.

As HSI separates light into more bands it therefore needs more light – which forms the basis for the concept of Hyperspectral cameras being “light starved”. Halogen is still largely used as a light source for HSI due to its low cost and flat spectrum. Learn more from our whitepaper titled Illumination in Hyperspectral and Multispectral Imaging.

The Main Differences between Hyperspectral and Multispectral Imaging

While both hyperspectral and multispectral imaging techniques are based on capturing and analyzing images across multiple wavelengths, there are significant differences between these two approaches. Understanding these differences is crucial for engineers and system designers looking to leverage spectral imaging for their applications.

Spectral resolution

Hyperspectral imaging provides a much higher spectral resolution by capturing a large number of narrow and contiguous spectral bands, often spanning the full sensitivity range of a sensor type (for example, InGaAs sensors operating from 1000nm to 1750nm). In contrast, multispectral imaging captures images at fewer discrete wavelengths, typically focused on specific wavelengths or bands of interest where there is a known response. The higher spectral resolution in hyperspectral imaging allows for more precise identification and characterization of materials.

Number of bands captured

Hyperspectral imaging can acquire tens to hundreds of spectral bands, providing detailed spectral information for each pixel in the image. Multispectral imaging, on the other hand, typically captures a smaller number of bands, often ranging from 3 to 10.

Data Volume and Processing Complexity

Due to the larger number of spectral bands captured, hyperspectral imaging generates significantly larger data volumes compared to multispectral imaging. This poses challenges in terms of data storage, transmission, and processing, which further requires specialized algorithms and computational resources to extract information.

System Requirements

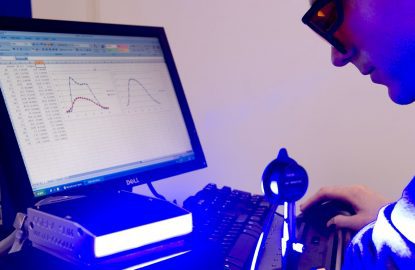

In Multispectral imaging, you need a good match between the wavelength and the ‘signal’ you’re looking for in the material. Let us take water as a classic example: liquid water has absorption bands around 1950nm, 1450nm, 1200nm and 970nm. So, if you were trying to image water, you would want wavelengths that match those. Intensity is another important factor in Multispectral imaging – the stronger the intensity of the light source, the stronger the response.

However, in hyperspectral imaging, the flatness and stability of the spectrum is actually more important. In this scenario you’re looking for “how does the product respond at 435nm as opposed to 440nm”, for example. So, if the intensity of the light is different at 435nm compared to 440nm, then the response will be different too. Camera gains can compensate for this difference but at the expense of increased noise.

| Hyperspectral Imaging | Multispectral Imaging |

| 100+ Spectral bands (up to 450) form a continuous spectrum | 3-10 Spectral bands which are discrete and separated |

| Higher level of spectral resolution & complexity | Limited spectral resolution & simpler processing |

| Offers more flexibility | Not as flexible |

| Expensive to set up | Cheaper instrumentation & set up |

| Can be a bit slower | Faster production speed |

Applications and Use Cases

Hyperspectral imaging excels in tasks that require detailed material identification and characterization, while Multispectral imaging is often suitable for applications where specific, targeted information about objects or scenes is required.

Food Sorting Industry

MSI based vision systems are well suited for defect detection on vegetables, and fruits like apples, strawberries etc. While HSI is employed for a detailed analysis, for example fat content or moisture level of an avocado, to ensure high-quality product.

ProPhotonix supplied a COBRA MultiSpec LED line light to a customer to improve their food sorting process and identify different contaminants with higher inspection rates, increased throughput and greater accuracy. Read more in this case study.

Recycling Industry

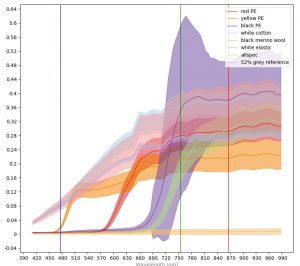

In textile recycling, three broad textile types exist: textiles encompassing man-made, plant-based, and animal-based fibers. The use of hyperspectral wavelength bands, and the varying spectral response to these wavelengths from each of the material types, can be used for differentiation as well as quantification analysis of material blends. The response curve of a reflectance spectrum can highlight many features unique to specific fibers, whether they are manmade, plant-based or animal-based fibers or a blend of fibers.

ProPhotonix recently worked with a customer manufacturing textile recycling machines to aid the separation of different textiles and improve the effectiveness and detection capability of their vision systems. Read the full case study for details.

Medical and Pharmaceutical Industry

Hyperspectral and multispectral imaging techniques are increasingly being explored for non-invasive disease detection, tissue characterization, and real-time imaging during surgical procedures. Machine vision lighting is now being used to accurately image data matrix codes (DMCs) on medical devices and produce adequate contrast in reading DMCs on all injection-molded capsules- learn how.

Inspection and Quality Control

In industries such as printing, automotive, electronics, pharmaceuticals, multispectral imaging and hyperspectral imaging enables non-destructive testing, defect detection, and quality assurance. High-value industries such as currency, pharmaceuticals and electronics use visible, UV, and IR light to identify either absorbing or reflecting taggants. Learn how ProPhotonix configured a machine vision solution for currency inspection system to inspect infrared taggants.

Conclusion

While both approaches capture images across multiple wavelengths, they differ significantly in terms of spectral resolution, number of spectral bands, spatial resolution, data volume, and applications. If your application requires a detailed imaging model sensitive to small changes, then hyperspectral imaging might be the best choice. But if you are only looking for specific, targeted information for known responses, multispectral imaging is the way to go.

Given the complexities and nuances involved in spectral imaging, seeking guidance from lighting experts becomes essential for choosing the appropriate imaging technology. ProPhotonix’s team of experts can guide you through the intricacies of selecting the most suitable lighting for your spectral imaging technology, helping you achieve optimal results.

Explore further into our offerings encompassing multispectral imaging solutions and hyperspectral imaging solutions. Contact us and receive free professional advice now.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.