This post looks at why you would choose LED machine vision lighting over traditional illumination sources. All information has been updated for 2019.

Illumination is a critical part of any vision system. The ability to identify a defect depends directly on the capacity to generate image contrast, which in turn relies on illumination level, spectrum and geometry. In most cases, LED machine vision lighting provides the optimum solution and can be the difference between a high quality, reliable and stable system and one that is less reliable.

When considering which illumination source is appropriate for a particular application, OEMs and system integrators evaluate factors such as:

- Intensity

- Cost

- Form factor

- Uniformity &

- Maintenance

LED vs. Traditional illumination sources

Traditional illumination sources such as halogen, incandescent and fluorescent were the light source of choice in the past. However, these illumination technologies and products no longer meet all of the requirements of today’s complex machine vision systems.

(i) Fluorescent Illumination

Fluorescent illuminators were one of the most commonly used illumination solutions for OEMs and system integrators due to their low cost. Fluorescent illuminators consist of tubes of mercury vapor that are excited by alternating current. Light is created when UV emissions cause phosphors on the walls of the tube to fluoresce with white light. While fluorescent light sources may be economical, they have a number of disadvantages:

- Relatively low intensity

- Unstable due to variation in color temperature

- Cannot be easily intensity controlled or strobed

- Environmentally unfriendly

Lower intensities can limit line speed in production environments while variation in color temperatures causes issues with image quality. Intensity control and strobing are important tools in modern vision systems. While initial costs for fluorescent lighting may be lower, disposal and environmental costs are an issue with this technology.

(ii) Fiber-Delivered Halogen (FDH)

Fiber-Delivered Halogen (FDH) has also been a popular choice for high-speed linescan applications. Halogen light sources were once the illumination source of choice where an increased intensity light was required. The halogen light source is created from a halogen bulb which emits broadband black body radiation. The bulb is mounted on a reflector and directed at a bundle of optical fibers where sufficient intensities are generated at the ends of the fiber bundles. Although halogen provides a high intensity light source, it is limited due to:

- Short lifetime (<3,000 hours)

- Susceptibility to color change over time resulting in changes in the system performance

- Lack of design flexibility for incorporation into an existing system

- High operating cost

The short lifetime of this technology is a critical issue resulting in high operating costs. In addition to replacement costs, because the light’s color changes as it ages, adjustments will need to be made to the system regularly to take account of these changes.

(iii) LED Machine Vision Lighting

LEDs are a semiconductor light source. LED devices are manufactured when LEDs are mounted and connected to a printed circuit board. Light is created from the LEDs on the board when current is passed through a PN Junction wafer of semi-conductor material. Intensity with LED illuminators is not only very high but with a proper controller and software can also be varied as and when needed; including strobing.

LED machine vision lighting provides reliable compact solutions suitable for a wide range of applications due to:

- High intensity

- Uniformity

- Cost efficiency

- Strobe capabilities

- Longer lifetime

Why Choose LED Machine Vision Lighting?

LED technology has transformed the way illumination is provided in machine vision applications. With advances in LED technology, illumination has become more adaptable and controlled. LED machine vision lighting provides quality, high performance, longer lifetime, cost-efficient illumination solutions that meet customers demanding application requirements. In almost all applications LEDs are now favored over traditional halogen and fluorescent sources in machine vision lighting.

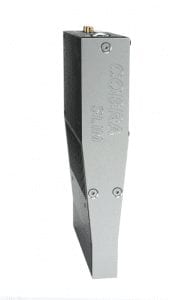

ProPhotonix utilize Chip-on-Board LED technology to maximize the value delivered by LED technology.

To learn more about our range of LED Lights, click here.