When vision system is an essential part of your quality assurance process, optimized lighting can increase inspection speeds and improve accuracy and product quality – ultimately adding to the bottom line. But optimizing illumination in an application is not a simple task. There are often a variety of physical and environmental obstacles present that translate to optical challenges. Additionally, there are frequently application-specific challenges that need to be addressed with optimized optics such as achieving appropriate contrast in a target or meeting high-speed inspection requirements. Therefore, many applications can benefit from a custom development approach to provide optimal lighting, which means optimizing optics for the custom lighting solution is necessary.

To ensure the challenges you are facing can be addressed with your custom LED solution, optics are one of the most important elements to understand. Let’s look at a variety of considerations that need to be made to ensure optical design is optimized in a custom LED light.

Physical Constraints of the Operating Environment Ultimately Impact Optical Design

Many of the optical decisions that need to be made when designing a custom LED lighting solution are correlated to the physical and environmental conditions where the vision system is operating. First, the location where the light can be placed is often restricted and will dictate the distance between the light, the target, and the camera. This fixed location will likely impact light intensity and the nature of illumination. The space available for the actual light may also be limited, which can impact both the angle of illumination and how compact the light needs to be.

When any unique, or challenging factors of the operating environment that will impact the way light is delivered are understood, the focus can shift to optimizing the optical design. In this post we will first explore how to optimize optics to achieve better contrast, which ultimately will lead to higher quality images and more precise defect detection. Then, we will look at how to continue optical optimization to increase inspection speeds, resulting in more efficient production.

Achieving Better Contrast to Acquire Higher Quality Images

The accuracy of a vision system inspection system largely comes down to the level of contrast that can be achieved within the acquired image between the features of interest and the background. This is directly related to how well the optics are optimized in areas such as the geometry of the light, wavelength, and the nature of illumination

Light Geometry

The geometry of the light beam is dictated by the physical location required for both the light source and the camera as well as certain characteristics of the target being inspected including the shape, surface structure, and material. These fixed characteristics of the application are considered together to determine the best angle of illumination for optimal illumination, which could result in using front or back lighting (Figure 1).

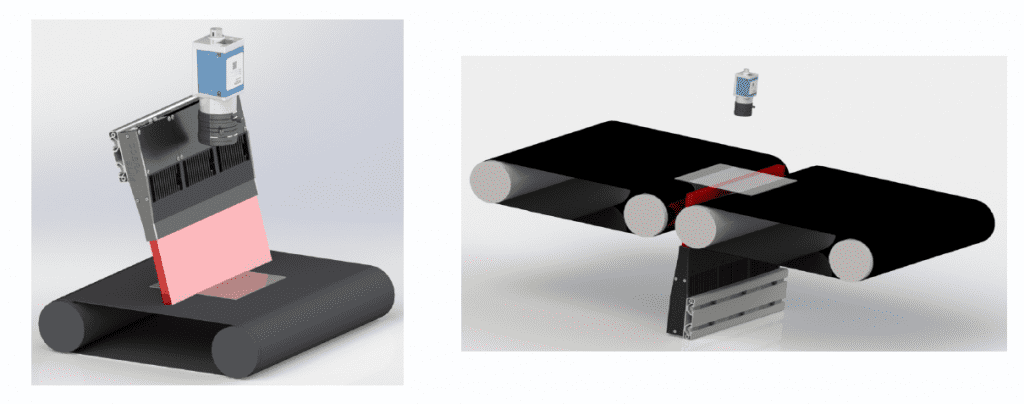

Figure 1. The rendering on the left shows a vision system system using front lighting while the rendering on the right shows a setup with backlighting.

With front lighting, there are two general techniques to consider. The first is bright-field illumination, which involves lighting the target so that light is uniformly reflected into the camera. The second is dark-field illumination, where most of the light is reflected away from the camera and only light that interacts with features of interest such as scratches or debris on the surface are reflected into the camera. When working with bright-field, the light can be placed on-axis or off-axis. With on-axis lighting the light is coming from the same viewing angle as the camera, or a low angle, while off-axis lighting is generally mounted about 15 degrees off perpendicular with the camera remaining perpendicular to the target. In backlighting systems, the camera and illuminator are on opposite sides of the target as shown in Figure 1.

Wavelength

We also need to consider the appropriate wavelength to best enhance contrast. There are a variety of characteristics of the object being inspected that will impact the decisions regarding wavelength including reflectivity, the ability to transmit or absorb light, or the fluorescence properties of the target material. After considering these characteristics we can select any wavelength ranging from broad-spectrum white light to narrowband red, green, or blue (RGB) lights to non-visible infrared (IR) or ultra-violet (UV) lights. Aided by our Chip-on-Board (COB) technology we can place these different wavelengths of LEDs close together to develop a multispectral lighting solution with an optimized blending of light.

Illumination Properties

The nature of illumination for any vision system application involves several important optical decisions that are impacted by the characteristics of both the physical environment and the target material. First, we need to determine if direct or indirect lighting is best for highlighting the area of interest. With direct lighting, a defect will show up bright on a dark background while indirect lighting makes the defect appear dark and the background is bright.

Then we need to determine if the light should be divergent, focused, or collimated. We also need to decide if the light should be direct, diffused, or structured. For example, adding an appropriate diffuser can help homogenize light intensity, which is crucial for inspecting surfaces that are reflective, polished, glossy, or metallic. Polarizers may also be used when glare needs to be reduced or removed

Finally, there are also indirect impacts in the operating environment to consider in our optical decisions for optimizing contrast. For example, if there is a lot of background light, we may want to consider working within a narrow spectral band or incorporating a filter to block out all other light colors and eliminate potential adverse impacts from background light.

How Do We Maximize Throughput?

Once we have optimized and customized the optics of our LED lighting solution to ensure we are capturing a high-contrast image, the next set of features we need to consider revolves around optimizing optics for image acquisition speed. In general, faster line speeds require more light, and there are a number of ways in which optics can be optimized to achieve higher line speeds.

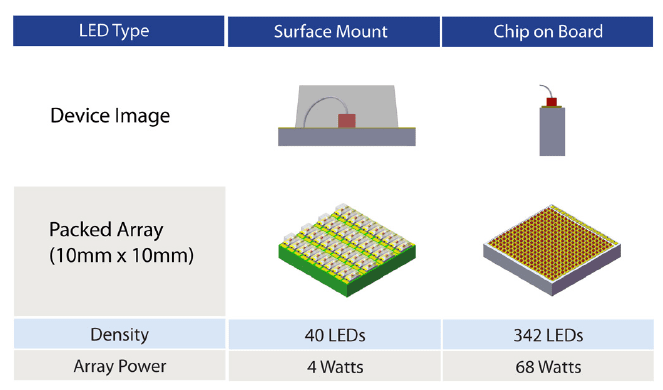

To start, we can increase speed with more intense light in a custom LED solution for a given size of illuminator by building LED solutions using COB technology. As shown in Figure 3, compared to surface mount technology, COB allows for a much higher packing density. As a result of this higher source density, we can provide more light (10X more light).

Figure 2. A comparison of the packing density and power of an LED lighting solution built with surface mount versus COB technology.

We also focus on optical efficiency, which is how much light is actually getting from the LED to the target. First, we can optimize the efficiency of the LED semiconductor sources and how they are thermally managed to make for a more intense source. Then, we can use our expertise in optical design and optical modeling to optimize the components in the optical path between the source and the target. This can be an extremely subtle and detailed process where we can make tweaks to properties such as the curvature of the optical surfaces. With both of these parameters optimized to generate as much light as possible, inspections can occur at higher speeds. Additionally, another adjustment we can make to increase inspection speed is to slelect the wavelength so that it is optimized for the sensors in place in the inspection application, but only if this will not impact contrast.

Overall, optimized optics are critical to ensuring a good quality image is captured by the vision system camera that highlights the features of interest and allows the system software to quickly and easily detect any issues. Obtaining a good image can result in faster processing times, faster line speed, and higher-quality products.

The ProPhotonix Partnership Approach to Optimizing Optical Design

At ProPhotonix, we partner with customers to define their optical requirements to customize vision system LED solutions that will enhance contrast and ultimately increase product quality while performing inspections at faster speeds. To do this, we work closely with customers to understand the requirements and constraints of their application and then to develop a complete lighting specification.

We also understand that the design process is all about managing compromises and tradeoffs, thus, we use our modeling expertise to explore the impacts of potential tradeoffs to create the best possible optics. With a custom LED solution with optics optimized to enhance contrast and inspection speed, more defects (or features of interest) can be quickly identified. This translates to increased product quality and overall efficiency gains that will impact the bottom line, resulting in a quick return on investment for your custom LED solution.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.