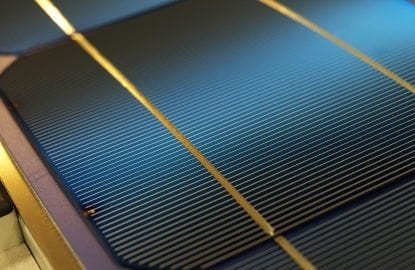

Thermal Management is a key consideration when designing a LED illuminator for machine vision lighting but often the most overlooked requirement. LED Lighting provides high intensity, high performance illumination especially when utilizing Chip On Board LED high-density packaging technology. When an electrical current passes through the P-N Junction (the active region inside the LED Chip) of a LED, light and heat occur. The heat, if unmanaged, can degrade the performance of the LED over time.

Why is thermal management in Machine Vision Lighting so important?

The majority of LED failures relate to excess temperature and poor thermal design. LED chips produce significant amounts of heat and sustained high temperatures adversely affect the basic structure of the LED chip. Elevated junction temperatures cause a reduction of light output and accelerate chip degradation. Only high quality LED illuminators have adequate, appropriately designed thermal management to overcome this.

Density and Environment

Simple illuminators may not require intense thermal management. However, high density packages, such as when utilizing Chip On Board LED technology in machine vision illuminators, will certainly require properly designed heat-sinking to drive the illuminator without damaging the LED. Demanding machine vision lighting applications require high irradiance illumination. To achieve these levels of irradiance, a high LED density source is required, which in turn, creates a high density heat source that must be thermally controlled.

Machine vision illuminators are often in systems where space is constrained or enclosed for environmental reasons. Constrained environments may have high ambient temperatures which further increase LED Junction temperatures.

Design

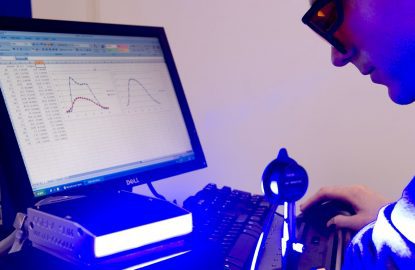

Thermal design will take the environment, LED packing density, specified run time, current drive rates, strobe flash, and correct heat-sink material into consideration to develop the proper solution. Good thermal design, with consideration to all variables, will ensure the efficacy of the LED illuminator and longevity of the chip.

Conclusion

Thermal management is a key consideration when designing high intensity LED illuminators for machine vision lighting applications. Properly designed thermal management allows the LEDs to be driven harder, maximizing light output, without degrading the lifetime of your product. ProPhotonix brings together more than two decades of comprehensive LED experience, unique engineering capabilities, and proprietary thermal modelling techniques to produce the highest quality, high intensity LED illuminators for the machine vision lighting industry and can also design and manufacture Custom LED Solutions to suit specific application needs.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.