Mercury lamps are a well-established UV light technology, but they have significant drawbacks such as use of toxic materials, filament instability, high heat output leading to constant recalibration and downtimes. Owing to changing customer demands, adaptation of new materials and the benefits of UV LED curing vs traditional systems, UV LED curing systems have emerged as the go-to-choice for a wide range of applications including printing, adhesives, and coatings.

Flexible form factors, multi-wavelength capability, greater control, stability, shorter cure time, greater energy efficiency, and reduced running costs are just a few factors which make UV LED curing systems better. If you have been considering moving from mercury lamps due to time-cost-performance issues, this blog post can guide you in selecting the right UV LED curing system for your business.

Determine Your UV LED Curing Requirements

UV curing is a photopolymerization process in which UV energy is used to change a liquid to a solid, by triggering photoinitiators in the liquid. UV LED lamps emit a narrower frequency range than traditional broad-spectrum mercury UV lamps. LED products are available in a range of wavelengths and customizable to specific application requirements making it easier to manage the narrow wavelength and match it with the photoinitiators’ trigger wavelength.

To optimize a UV LED curing system for various applications, it is imperative to consider the following factors-

Wavelength Selection

Choosing the right wavelength is vital for a high-quality cure in minimal time. For example, a 365nm light may be the optimum wavelength to cure based on the target materials absorption profile, 395nm may still produce a better curing result due to efficiency and “cost per watt” differences between the LEDs.

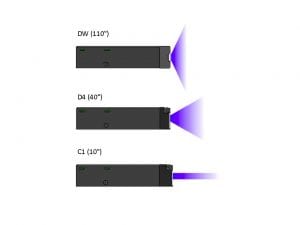

Light Output Profile

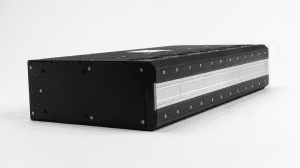

Defining the output profile for your UV LED curing system is crucial. Narrower light outputs may be necessary in certain applications to avoid unwanted curing, such as curing of material on print heads. ProPhotonix offers a range of light output configurations including low angle (collimated), medium angle and wide angle with the COBRA Cure FX series.

Working Distance

The working distance requirements of an application impact the LED lamp’s optical design. Although these UV LED curing systems typically work over a short working distance, certain applications may require a different optical system to provide a longer working distance and/or a wider depth of focus when curing objects of varying sizes.

Intensity & Dose

UV curable media require both a minimum intensity and a minimum dose for an effective cure. If the intensity is too high, it can damage the ink or resin. A balance needs to be struck between the required intensity and dose level.

If your application requires specific optical considerations, ProPhotonix can work with you to design application specific UV LED curing systems.

Evaluate UV LED Curing Performance and Energy Efficiency

The emerging UV LED market is leveraging all the expertise and supply chains built up within the wider LED industry to ensure a high performing reliable solution. In order to optimize curing in your application, it is important to understand the factors to consider when evaluating performance.

Uniformity

Uniform light is extremely important in UV LED curing systems as poor uniformity can result in uneven cure. Most UV LED lamps are capable of light uniformity, ProPhotonix LED lamps can help maximize it through custom LED substrate and optical design. Chip-On-Board LED technology allows a higher packing density resulting in higher intensity & greater uniformity for the curing system.

Irradiance

Irradiance, which is the measure of exposure per second on the target surface, is denoted by light intensity and is commonly expressed in watts/cm2. On the other hand, the dose of light energy at the curing surface is measured as radiant exposure (intensity x time) and quantified as joules/cm2. Measuring both the irradiance and dose and achieving a balance between the two is crucial in ensuring that curing conditions are optimized, and consistent results are maintained.

Additionally, the efficiency and effectiveness of UV LED curing systems depend significantly on their optical design, which ensures that the output generated by the system reaches the intended surface area of the target material and facilitates proper curing. Factors including direction of light, energy absorbed by in the UV curable film, and dose must be considered for an efficient optical design of UV LED curing systems.

Consider UV LED Curing Cooling Capability

As mentioned above, high peak irradiance and energy density are critical to UV curing, which often requires many LEDs operating at high current and voltage levels. This produces a lot of heat in the LEDs which needs to be removed as efficiently and as quickly as possible for maximizing their lifetime, reliability and performance. To this end, good thermal management is crucial.

For a low intensity, cost-sensitive application requiring a compact form factor, a convection cooled lamp would be most suitable. With a higher intensity requirement, provided that the space is available to allow some increase in form factor, a fan-cooled solution may be ideal. Where space is restricted, but high intensity is a must, then a water-cooled solution may be required.

Assess UV LED Curing Compatibility and Cost

Compared with traditional lamp systems, LED systems offer significant benefits over the life of the lamp. Mercury lamps have short lifetimes and so require frequent replacement. LEDs allow instant-on/off, resulting in lower operating costs and have extended life which reduces maintenance costs.

For bigger UV LED setups, replacing the entire lamp can be expensive and cause production delays. A solution to this is to use stackable or modular lamps. Stackable lamps can be put next to each other, creating a larger unit. Each lamp can be powered separately or connected to a shared power supply. Modular systems are similar but are designed to be part of a complete setup and can’t work independently. Both options save costs and are great for different lengths.

Return on Investment (ROI)

The ROI is a measure of an investment’s efficiency and can be calculated by dividing the benefit of the investment by its total cost. ROI reflects the profitability of a project. When calculating ROI for an investment in UV LED Curing systems, it is important to consider reduced downtime, increased energy efficiency and flexibility.

Conclusion

UV LED curing systems offer new capabilities that cannot be achieved with conventional curing technology. They offer reduced operating costs, highly efficient energy consumption, lower maintenance costs, longer lifetimes, low production downtime, increased operating efficiency and enhanced control capability.

However, before proceeding with a UV LED curing system it is necessary to evaluate compatibility with specific application requirements for the best results. With more than two decades of experience in designing and manufacturing LED solutions for OEMs worldwide and over 15 years of experience in working with UV LED solutions, ProPhotonix’ team has the experience and expertise to work with you through a customer-driven project process, delivering a reliable, complete UV LED curing solution.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.