Laser modules are critical components in many advanced applications, and their performance and longevity can be influenced by various factors. In this fourth installment of our ‘Tech Notes’ series, we delve into two of those factors- Reverse Polarity Protection and Overvoltage Protection. This note will explain these protection mechanisms in detail, highlighting how they work and why they are essential for maintaining the reliability and functionality of laser modules.

What is Reverse Polarity Protection?

Reverse polarity occurs when the positive and negative power leads are connected incorrectly, posing a significant risk to electronic devices. This mistake can happen during installation, maintenance, or testing phases, potentially leading to irreversible damage to sensitive components like laser diode modules.

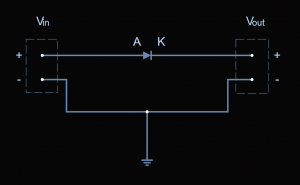

To mitigate the risk of reverse polarity-induced damage, reverse polarity protection is employed. One common method involves the inclusion of a diode in series with the power supply line. When the polarity is correct, the diode allows current to flow through the circuit as usual. However, in the event of reverse polarity, the diode effectively acts as an open circuit, isolating the rest of the system and preventing reverse currents from causing harm.

By employing reverse polarity protection, laser diode modules are shielded from the adverse effects of reverse voltage, ensuring their reliability and longevity.

In what applications is Reverse Polarity Protection important?

Reverse polarity protection is particularly crucial in applications where laser-based systems draw substantial current. In such scenarios, the potential for damage due to reverse polarity is heightened, necessitating robust protective measures.

There are two primary approaches to ensuring reverse polarity protection in laser systems. Firstly, selecting circuit components inherently capable of withstanding reverse polarity can mitigate the risk of damage. Alternatively, integrating reverse polarity protection circuits, such as diodes, provides an additional layer of defense against unexpected polarity reversals and high current surges.

Reverse Polarity Protection – What ProPhotonix can offer

At ProPhotonix, we prioritize the reliability and longevity of our laser modules. All our laser modules are engineered with dedicated reverse polarity protection circuits designed to withstand anticipated reverse voltages.

What is Overvoltage Protection?

Voltage spikes or overvoltage conditions occur when the power supply exceeds the maximum rated voltage. An overvoltage condition could be due to a power surge, electrostatic discharge, or a fault in the distribution line. It is crucial to protect laser modules or laser-based systems from potential overvoltage damage as it can degrade the components or lead to system malfunctions or worse, fire.

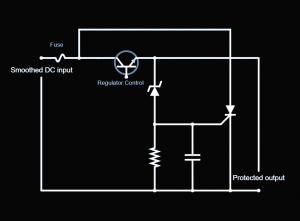

Overvoltage protection often consists of an integrated circuit which monitors the power supply and clamps the output when the voltage exceeds a threshold level. Another approach is to include a voltage limiting device within the laser module. This can be done by connecting the circuit internally or externally depending on the circuit design, mode of operation, sensitivity and overall application of the system.

In what applications is Overvoltage Protection important?

Overvoltage protection is essential in any application where power fluctuations or electrical disturbances are expected, including medical equipment, industrial settings and even consumer electronics. Without proper overvoltage protection, laser modules are vulnerable to damage from voltage spikes, which can lead to costly repairs or even complete failure of the device.

Overvoltage Protection – What ProPhotonix can offer

All our laser modules are designed with a parallel device called a transient voltage suppressor. When the supply voltage exceeds the threshold voltage, the voltage suppressor prevents it from exceeding any further by either activating the power supply, current limiting circuit or by blowing the fuse. This threshold value is set by considering the magnitude and duration of potential surges. The power supply might get damaged but the laser diode or module within your system will stay safe.

With over two decades of experience, ProPhotonix manufactures reliable, high-quality laser modules by sourcing laser diodes from high-quality manufacturers and managing the entire design and development process in-house. Trust ProPhotonix for robust protection and superior laser technology. For more information, contact sales@prophotonix.com.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.

ProPhotonix laser module range includes laser modules by beam shape including crosshair lasers, line lasers and dot laser modules. Contact us for free expert advice on selecting the optimal solution for your system.