Wavelength selection is critical in curing applications. The optimum wavelength decreases curing time and improves the overall quality of the cure. Generating energy most efficiently in the 365-405 nm ‘UVA’ wavelengths, LEDs are characterized by intense peaks with narrow bandwidths compared with traditional lamp technologies. The optimum wavelength used for UV curing will depend on a number of factors. The LED wavelength should match as closely as possible the peak of the absorption profile of the target material. However, this is not always the case. In some cases, the efficiency of LEDs at a wavelength located lower in the absorption profile of the target material may perform better than one located at the peak of the absorption profile due to its higher efficiency.

When the LEDs’ intense peaks are optimally matched with the absorption profile of a photoinitiator, they cause the rapid curing of materials.

UV Curing, UVA, UVB, UVC, And UVV Wavelength Ranges

What Is the Difference Between UVA, UVB, UVC, and UVV?

The ultraviolet region covers the wavelength range from 100nm to 400nm.

UVV covers the range from 395nm to 455nm. UVA is the region typically used for UV curing applications and ranges from 315nm – 400nm and are the most widely used LEDs today. UVB is the range from 280nm to 315nm and UVC is the range from 100nm to 280nm. UVC LEDs are a relatively new technology that is rapidly improving and is predominately available from 265nm to 285nm. UVC LEDs cure the top surface very well but are not as effective as UVA wavelengths at curing into the bulk of a material.

What are the Different UV Wavelengths?

In UV LED curing applications, the typical wavelengths used are 365nm, 385nm, 395nm, and 405nm.

Select the most effective wavelength for a UV Curing LED system.

Selecting the most effective wavelength for a UV LED Curing system is critical in curing applications as the optimum wavelength decreases curing time and improves the overall quality of the cure. For example, while 365nm light may be the optimum wavelength to cure based on the target materials absorption profile, 395nm may produce a better curing result due to the efficiency differences between 395nm and 365nm LEDs.

In recent years, LED technology has advanced in both output power and available wavelengths. Working closely with a UV LED curing systems manufacturer will help to identify the most effective LED solution for your application.

UV Curing Applications

UV LED curing systems are now the technology of choice across a wide range of applications including:

- Printing

- Industrial Printing

- Digital Printing

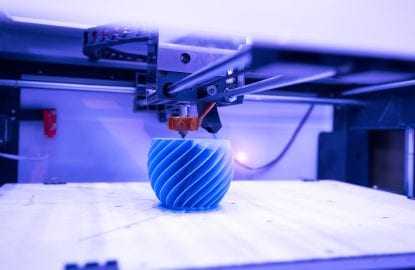

- 3D Printing

- Coatings Applications

- Adhesives

Understanding UV Curing

To learn more about UV LED Curing systems, discover the COBRA Cure FX Series, visit our dedicated blog section on UV LED Curing Systems or contact our team for free expert advice on UV Curing systems.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.