Diode lasers have become indispensable tools across numerous industries. Be it industrial alignment or in medical or dental equipment, there is a progressive need for devices with higher optical performance, and more precise control. To achieve this, it is crucial that engineers and system designers have a thorough understanding of the key parameters that affect laser diode performance. This blog highlights the key parameters that define laser diode performance and potentially help boost the overall performance of your laser-based system.

Key Parameters Affecting Laser Diode Performance

Before we dive into the specifics, let’s take a broad look at how laser diode work.

A laser diode is, first and foremost, a light-emitting diode with a semiconductor (p-n) junction working as the active light generating medium. As current flows across the p-n junction, the energy bandgaps of the semiconductor material trigger the generation of photons. When these photons interact with electrons from the n region of the junction, another photon is emitted. A laser diode is built with reflective mirrors to form an ‘optical cavity’ such that the emitted photons reflect internally, inducing absorption and faster emission. This process in turn enhances and amplifies the intensity of the light emitted by the laser diode.

With an applied forward voltage, laser diodes behave like other semiconductor diodes but as the current increases, a variety of factors come into play to impact the performance of the laser diode. Let us dive deeper into those parameters-

Wavelength

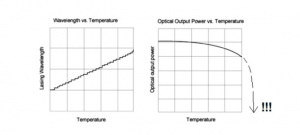

Semiconductor materials used in a laser diode determine the emission wavelength as the bandgap energy of the materials used control the output. Changes in temperature and current affect the bandgap of the p-n junction and thus can be used for better tunability of the laser diode. For example, Aluminum is known to increase the bandgap energy and in turn, a shorter wavelength. Thus, we often see laser diodes with high aluminum content being used for applications requiring shorter wavelengths.

Power Output

Output power is another temperature sensitive parameter, and the choice of laser diode also influences it greatly. The design and capability of the laser diode also determine actual power output. Continuous-wave (CW) lasers produce continuous power 24*7 while pulsed lasers produce high peak power for a short period of time. This makes pulsed lasers suitable for spot welding, pump-probe spectroscopy applications while CW lasers are well-suited for medical diagnostics, scanning microscopy, and sorting applications.

Efficiency and Conversion Efficiency

Laser diodes can never be 100% efficient as some of the input power is often lost in the optical cavity either due to the presence of minute impurities or imperfections. Power loss in high-power laser diodes is associated with the following factors- joule heating, carrier absorption, hetero-junction band alignment, carrier leakage, and below-threshold loss (1). Improvements in the diode laser design such as a better cooling system to reduce the losses can result in higher conversion efficiency at the target operating current.

Threshold Current and Operating Current

As current is injected into a laser diode, it begins to emit light- defined by the Output Light vs. Input Current curve (L-I Curve). The threshold current (minimum current required to initiate laser action) is required to be as low as possible for higher efficiency. Threshold current depends on the semiconductor material, laser diode design, and its form factor. Operating current of the laser diode also plays a pivotal role in defining its performance and longevity.

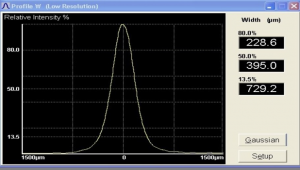

Beam Quality and Divergence

Laser diodes produce an elliptical beam (see Fig below). A variety of optical components may be used and are positioned to alter the beam shape including collimating lens, prisms or more complex multi-lens designs. For example, a single collimating lens produces a collimated elliptical beam or focuses the beam on a smaller spot at a specific working distance. Additionally, the beam shape can also be altered depending on the choice of diode. For example, single mode laser diodes without additional optics can produce a more circular beam with a smaller divergence angle between 10° to 15°. While multi-mode diodes produce a more elliptical beam with larger divergence angles from 10° to 30°, or as much as 40° in the other direction.

These differences are important for specific applications to achieve the required beam shape, quality and divergence. For applications such as industrial alignment, several parameters including beam quality, beam shape and boresight accuracy play a role. To achieve perfect alignment with high throughput, these parameters must be adjusted for perfect beam delivery to the target area.

Temperature Sensitivity and Thermal Management

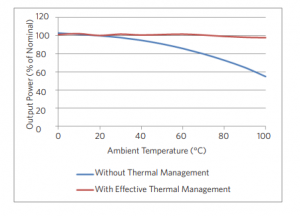

As we have seen above, wavelength, output power and overall efficiency of the laser are highly dependent on temperature. As the temperature increases for a given fixed current, the output power decreases. Overheating of the diode laser can also lead to wavelength instability, degradation of beam quality and high beam divergence.

To maintain stable operation and extend the lifespan of laser diodes, effective thermal management is essential. Operating temperature can be compensated by electronics such that individual diode temperature does not impact output power.

Spectral Characteristics

Poor laser system design, imprecise fiber coupling and ineffective heatsinking are some other factors that can impact laser power stability and its accuracy. The type of packaging used for the laser diode such as TO-can or butterfly package can also impact performance depending on the robustness of electrical connections, contact for heat transfer, and suitable coupling of the output light.

Conclusion

To harness the full potential of laser diodes in your applications, consider these parameters carefully and tailor your laser diode selection and operational practices accordingly. If you’re looking to explore high-performance laser diodes to elevate your laser-based systems, visit our Laser Diode Page to view a wide range of wavelengths and power outputs. ProPhotonix has the expertise to help you in selecting the right laser diode for your specific application. Let us help you find the perfect laser diode solution to meet your specific needs and optimize your system’s performance.

Sources:

1. Chuanwang Xu, Aiyi Qi, Juwen Wang, Hongwei Qu, Liang Wang, Fansheng Meng, Renbo Han, Ting Fu, Xuyan Zhou, and Wanhua Zheng, “Doping profile architecture towards lower loss and higher efficiency for laser diodes,” Opt. Express 31, 27894-27904 (2023)

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.