Laser diodes for any application, engineers, technicians and procurement specialists generally refer to certain specifications that their system or application requires. When you buy laser diodes, there are certain criteria that ensure the correct laser diode is chosen for your application.

Below we have listed 5 key considerations when choosing laser diodes for an application:

1. Manufacturer

Choosing the correct manufacturer is important. A good laser diode manufacturer will enable a reliable supply of high-quality laser diodes for your application. ProPhotonix works closely with a number of high-quality laser diode manufacturers and deal directly with engineers on the latest technology allowing access to the most up to date advances in laser diode development as well as a broad product range to suit diverse application needs. ProPhotonix distributes laser diode products from high-quality manufacturers including Ushio, Osram, Panasonic, QSI and Ondax.

2. Wavelength

The choice of wavelength for your laser diode may be determined by your application. For instance, in barcode scanning where a visible red output is required, a 650nm wavelength is often the optimum choice. In other cases, the wavelength would be chosen in relation to how the light interacts with a given medium, such as scattering from smoke particles, absorption by skin tissue, or fluorescence of different particles. Cost may also drive an element of wavelength choice. In some applications, it may be possible to use laser diodes commonly used in high volume markets such as 405nm laser diodes used in Blu-ray. This will bring significant benefits in terms of cost. Other applications may require tight tolerances of specific wavelength.

3. Power Output

The laser diode application will dictate the power requirement. For instance, a patient alignment application may require <1mW, however, in 3D scanning a diode with output power >50mW may be necessary to optimize image contrast. A key consideration when determining laser diode specification is compliance with laser safety classifications.

In general, it is best practice to over-specify a laser diode by at least 20% more power than required. This will allow capacity for unanticipated power spikes and also ensures maximum diode lifetime.

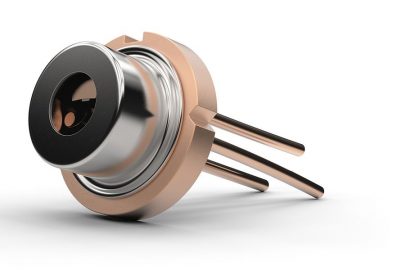

4. Pin Configuration

Most devices are generally available in a number of pin configurations connecting the laser diode and photodiode anode/cathode to the case of the device.

The choice of pin type is important to determine the housing polarity when mounting the device; and whether any electrical insulation is required.

5. Divergence Angles

This is important for optical designers in determining parameters such as circularity, minimum spot size, collimated beam divergence or coupling efficiency into an optical fiber. The divergence angles do vary within any given batch of laser diodes, so it is important to understand the manufacturer’s typical distribution. Often this can be narrower than the datasheet values provided.

A vendor with close ties to the manufacturer can generally supply extensive distribution data which can help improve manufacturing production yields.

Laser Diode Selector

Our Laser Diode Selector allows you to specify your wavelength, output power and laser diode package requirements, search by manufacturer or laser diode color and compare all laser diodes available and download relevant datasheets.

With over 20 years’ experience in distributing and working with laser diodes, ProPhotonix works closely with the R&D departments and engineers at all the major laser diode manufacturers – giving us access to the latest in laser diode technology and the technical capability to support you in your laser diode specification process.

If you have a question, or would like any further information, please Contact Us today.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.